Western Australia Iron Ore Overcoming Productivity Challenges

9 December 2015Few sectors have been under as much pressure to reduce costs and increase efficiencies as iron ore. An increasing number of mines in Western Australia are turning to technology and reporting operational improvements through training initiatives completed in partnership with Immersive Technologies.

Anglo American Utilizing Immersive Technologies’ Managed Services to Improve Performance at Los Bronces Mine

23 November 2015Immersive Technologies has over 80% market share of high fidelity training simulators in the mining industry with over 930 simulator modules deployed. Immersive has also grown to be the global leader in operator workforce development solutions for mining, and announced today the quantifiable results achieved to date in partnership with, Anglo American Los Bronces.

Immersive Technologies Announces Dedicated Learning Systems Business Unit

10 November 2015Immersive Technologies, the global leader in mining equipment simulators, has announced they are launching a dedicated Learning Systems business unit to service resource companies globally. This new business unit provides customised learning technologies and solutions to drive improved safety, profitability and efficiency. The solutions blend virtual reality, visualisation, e-learning and desktop simulation.

Immersive Technologies Expands Equipment Simulator Footprint in India

16 October 2015Thriveni Earthmovers, a fast growing Indian mining service provider, has advanced their training program with the introduction of PRO3-B Advanced Equipment Simulators from Immersive Technologies. Thriveni is committed to sustainable mining practices, taking care of the local society at large and improving the quality of tribal people’s lives by undertaking various local empowerment and social activities. In continuation of its strategy, Thriveni will use multiple simulators to increase the skills and safety of their existing equipment operators and to build a new professional work force from the local tribal community.

Middle Eastern Quarry Operator, Stevin Rock, Making Significant Operations Improvements Through Immersive Technologies’ Simulation Based Training Solution

19 August 2015The first simulation based operator training centre in the United Arab Emirates has achieved significant improvements less than a year after implementation. Stevin Rock, one of the largest mining groups in the world, has made improvements in safety, maintenance and productivity through Immersive Technologies’ simulation training.

Harper Government Expands Training and Skills Development Opportunities for Women with Simulators from Immersive Technologies

4 August 2015The Honourable Michelle Rempel, Minister of State for Western Economic Diversification, announced an investment of $2,097,375 to expand the Women Building Futures’ (WBF) Heavy Equipment Operator (HEO) Program. Well-known companies such as Emeco, Finning Canada, Immersive Technologies, Imperial, Lehigh Hanson, Mammoet Canada Western Ltd., and SureHire, support the WBF HEO Program by providing WBF with access to services and resources that ensure women receive the skills and experience needed to pursue their careers.

Inaugural Class Graduates Ma’aden’s Saudi Mining Polytechnic

30 July 2015More than 150 students have successfully completed their two-year long coursework qualifying them to hold mining jobs in Saudi Arabia. As part of the program students were trained in both theoretical and technical programs at the world class training center, Saudi Mining Polytechnic, established by Ma’aden.

US Coal Miner Training Program Achieves 12% Improvements in Room and Pillar Production combining Experienced Operator Trainers and Immersive Technologies’ Simulators

15 July 2015Steep declines in the price of coal have created an emphasis for existing operators to boost their productivity. A recent simulator based training initiative by an underground coal mine in the eastern region of the United States aimed at Continuous Miner Operators led to nearly one million dollars in production improvements in just 90 days. The training program targeted 16 Continuous Miner operators from eight different room and pillar mines.

Russian Cat® Dealer Vostochnaya Technica to Deliver Operator Training Using Immersive Technologies Simulators

7 July 2015A technology centric vision to develop solutions that deliver additional value, increase productivity and enhance safety for Cat® equipment customers in Western and Eastern Siberia, Yakutia and the Northern part of Russian Far East has led to Vostochnaya Technica investing in Immersive Technologies’ simulators for operator training.

Technology Leaders Immersive Technologies and RCT Launch Remote Control Training Simulator

18 June 2015Immersive Technologies recently delivered an Advanced underground loader simulator complete with RCT ControlMaster® CM2000D line-of-sight remote control. The simulator will be used in Kazakhstan to comprehensively train miners in the safe operation of loaders in both manual and remote-control modes. Global technology leaders in the mine equipment training and advanced mobile-machine control fields have joined forces to deliver a unique remote control training solution designed to improve mine safety and profitability.

TECSUP Hits Technological Milestone with Equipment Simulator from Immersive Technologies

11 June 2015The teams from TECSUP and Immersive Technologies unveil the newest addition to the TECSUP training offering, an Advanced Equipment Simulator from Immersive Technologies. As operator excellence focuses more on technology integration, TECSUP has teamed up with Immersive Technologies to deliver the ultimate in operator training. Peru based TECSUP, a technology leader dedicated to educate and train professionals, will be using the latest Advanced Equipment Simulator from Immersive Technologies.

Kiewit Mining Group and PAMA Save Millions and Increase Safety Winning Immersive Technologies’ 2014 Business Improvement Awards

1 June 2015The annual recognition for mining companies using simulation for operator training and business improvement from Immersive Technologies was awarded to Kiewit Mining Group of the USA and PT Pamapersada Nusantara (PAMA) of Indonesia. The award recognizes the achievements of mine sites focused on improving operational safety, efficiency and productivity through strategic and focused simulator based training initiatives.

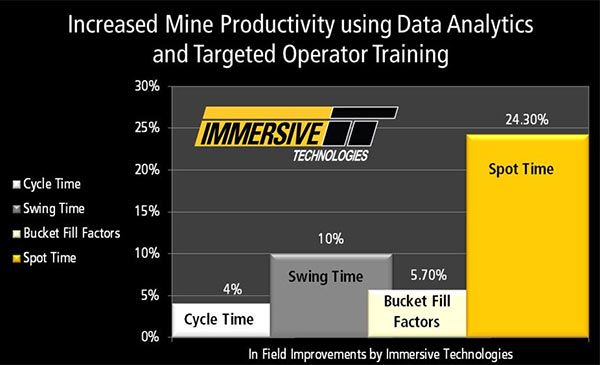

Increase Mine Productivity using Data Analytics and Targeted Operator Training

1 April 2015It’s one of the biggest challenges facing mine sites today, “how can we increase productivity without compromising safety or increasing cost?” Immersive Technologies, a leader in mining training solutions, says compelling results prove putting more focus on operator behavior and skills will deliver higher output. They recently released a number of case studies proving how their simulation training and professional services delivered cycle time, spot time, swing time and bucket fill factor improvements.

Simulated Process Operations Training (SPOT) from Immersive Technologies Delivers Safer and More Productive Plants

11 March 2015Immersive Technologies has released a new training solution for process plant operator training. Simulated Process Operations Training, SPOT™, maximizes plant uptime and throughput, improves safety and significantly reduces the time taken to train new plant operators. The global process industry loses annual production due to unscheduled downtime and poor quality with a significant amount of these losses being preventable and primarily the result of operator error. Through using SPOT, improvements in the skills and behaviors of plant operators can correspond to large improvements in plant production.

Immersive Technologies Wins 2014 Mining Magazine Environmental Excellence Award

3 March 2015Immersive Technologies has been recognized for their efforts in Environmental Excellence in the 2014 Mining Magazine Awards. Their simulator technology includes detailed monitoring of operator behaviors which directly relate to excess fuel consumption including levels of throttle and brake application for specific situations. This has resulted in an enhanced assessment tool for managers to determine which fuel inefficient operator behaviors are most prevalent on their site and represent the greatest opportunities for savings. Pictured with award are company founders Peter and Wayde Salfinger.

Mimosa Coal Mine Partners with Immersive Technologies for Operator Safety and Productivity

3 February 2015Changes in geological conditions causing increased facial outbursts led the Mimosa mine site to use a tele-remote operated system. The site anticipated decreased production levels with the new system but has worked with operator training company, Immersive Technologies, to develop simulation based training so miners can operate the equipment safely without production losses.

Immersive Technologies Provides Training to Prepare for Arriving Hydraulic Shovel Fleet at Large Copper Mine in Arizona

19 January 2015Immersive Technologies has delivered operator risk assessments, shovel control familiarization and emergency response training for a large group of experienced operators preparing for the arrival of a hydraulic shovel fleet at a large copper mine in Arizona. Immersive Technologies, the global leader in operator workforce development solutions for mining announced today that a major copper mining company in Arizona has chosen to have their shovel operators trained by Immersive in order to prepare for soon to be commissioned hydraulic shovels. This proactive approach to training is part of a strategy to ensure that newly commissioned equipment is run by confident operators who are already trained to be productive and safe.

Addressing Mining Industry Challenges Through Training

7 January 2015The Top 5 Global Mining Companies have trusted Immersive Technologies’ instructional design and training integration service at over 50 installations. The instructional design of mine operator training programs is one of the most critical elements in predicting operator performance outcomes. Equally important is developing a strategy for mine stakeholder readiness and technology integration to ensure training program sustainability.