We use cookies

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.

“We believe with the simulator we can get the new operators to the 75‑90% mark after three months.”

A well designed and standardized training program increases the ability of skilled operators, minimizes risk, machine abuse and increases the level of safety on your entire site.

Immersive Technologies offers mining operations a training solution that ensures high levels of staff readiness and operational improvement, while taking advantage of a range of technologies to ensure the most cost effective solution and scalable trainee throughput. This is done via blending eLearning, Instructor Led Training, Medium and High Fidelity Simulators, with customized content and curriculum to meet the needs of specific operations.

This mix of teaching methods has been proven to be the most effective way of engaging trainees and increasing learning retention.

eLearning is an interactive, self-directed computer application designed to present information and confirm employee comprehension and ability. It is the repository for key knowledge, both broad and specific. It can be viewed by everyone and helps create a base for learning so that everyone is on the same page.

Instructor Led Training creates an effective and consistent learning environment which allows for students to increase knowledge and skillset via questioning and discussion.

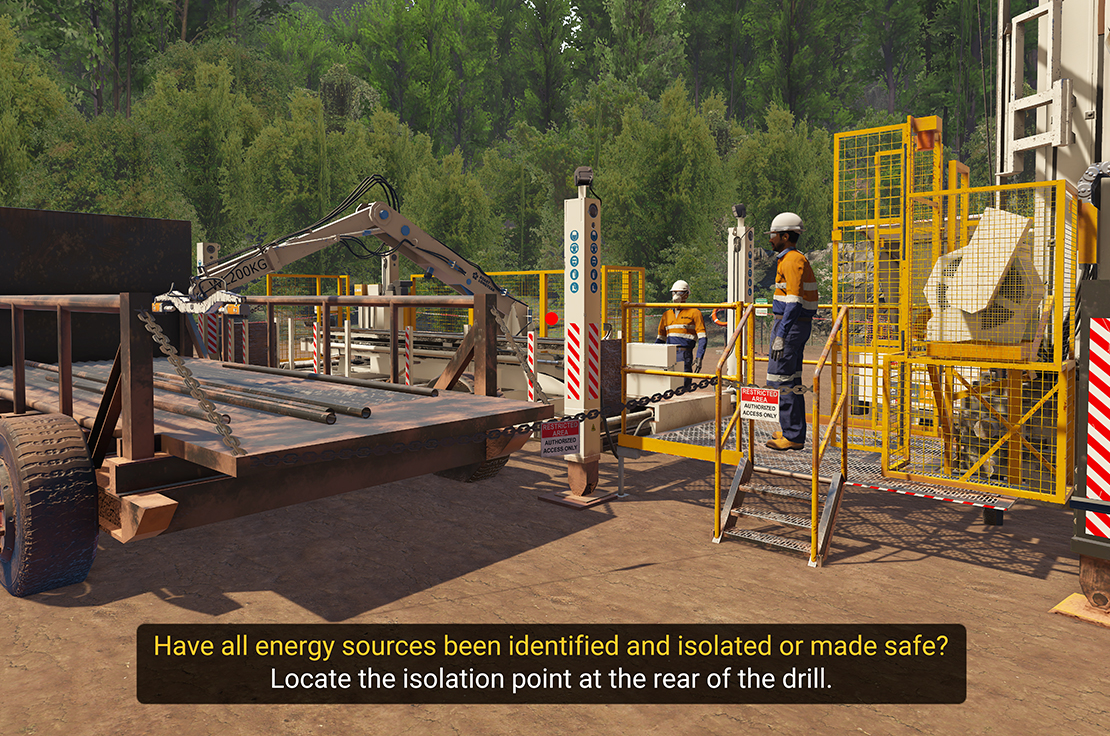

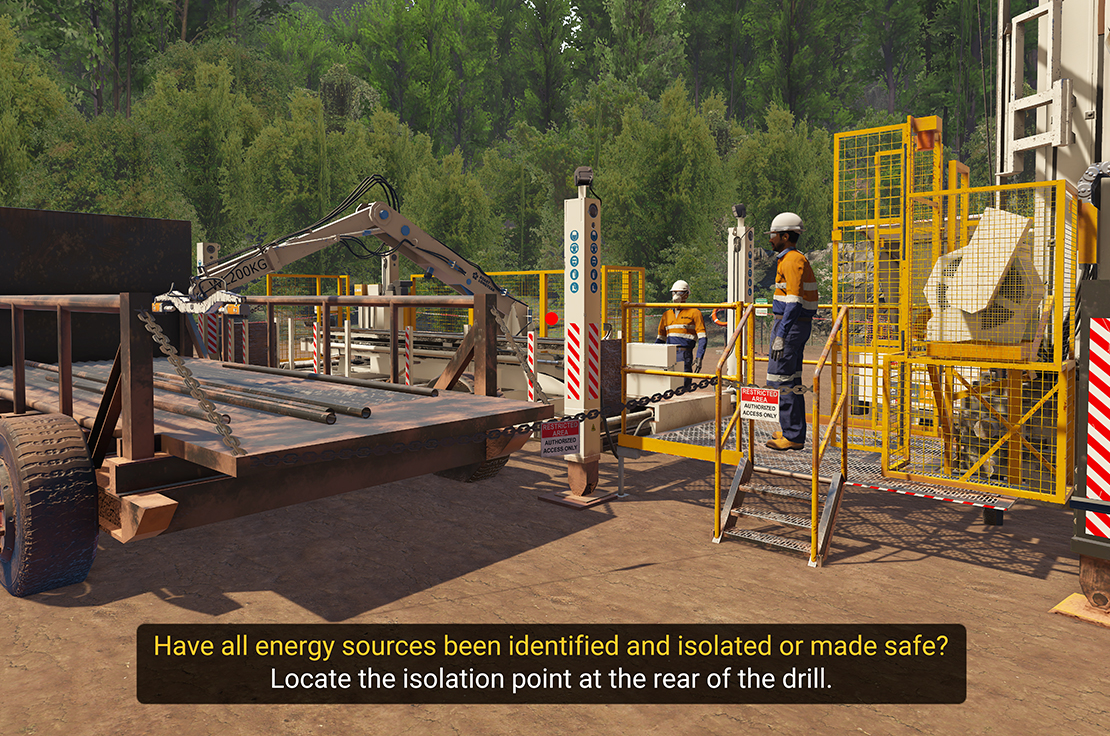

Simulation based training ensures green operators are skilled in machine operation before entering site operations, reducing the risk of machine damage and injury through lack of knowledge. It allows you to train operators on a multitude of scenarios and earthmoving techniques without hindering your production. Trainers can assess operators repeatedly on a range of operating techniques and emergency situations that are cost prohibitive to replicate on the actual machinery. For example; Engine fires, break failure and loss of steering control.

Simulation training has been proven to dramatically reduce risk, cost, unscheduled maintenance, increase trainer effectiveness and efficiency while maximizing productivity. Simulators provide operators a safe environment to learn and practice their skills. Because operators are consistently shown and assessed on the proper operator techniques they have a better understanding and knowledge of the real machine.

Let us show you how our solutions can drive results at your site.

REF#TR1324

Barrick, Tanzania

Barrick started a Women in Mining project to empower women in the community, providing them with the opportunity to enhance their skills and knowledge through a green operator training program.

This project delivered 100% pass rates for Sandvik TH545i driving assessments and a 66% reduction in errors per hour.

REF#PR3521

CSN Mining, Brazil

CSN sought to improve efficiency, reduce costs and increase productivity to counter falling commodity prices.

This project delivered a 50% reduction in green operator training time (from 6 months to 3 months) and 35% reduction in production equipment downtime for training.

REF#TR1221

Codelco, Chile

Radomiro Tomic faced challenges in training management for its intensive workforce - including creating and optimizing plans for time and cost efficiency, training effectiveness and operator retention.

Following the training program, results demonstrated a reduction of 111 training hours on equipment per operator, equating to savings of over USD 716,000. Training time was reduced by 61% (180 to 70 hours per operator).

REF#TR1018

AngloAmerican, Chile

Expansion of the truck fleet created demand for additional operators, however recruitment drives were producing hires that proved unsuitable during the training process. Site needed to improve the candidate screening process to reduce unsuccessful hires.

Following the project, 28% of unsuccessful hires were eliminated from the selection process, reducing the impacts of turnover at later stages of onboarding and employment.

REF#TR0816

PT Kaltim Prima Coal, Indonesia

PT Kaltim Prima Coal (KPC) projected 30% growth until 2030, and needed to recruit, maintain and develop operational capability to match site expansion.

This project demonstrated a reduction of 'on-equipment training hours’ from 40 to 25 (average) and reduction in green operator training hours from 546 to 310 (average).

REF#TR0716

PAMA, Indonesia

Due to massive growth of coal production, the company needed to expand by about 2,000 operators per year.

PAMA used Immersive Technologies simulator training to deliver a reduction of a 44% training time per operator.

“A key element has been the simulators ability to provide unbiased and measurable feedback…”

REF#UM1615

Iron Ore Mine, Australia

Integration of a new truck type effected a change in operating practice, exacerbated by the need for machine operators to be skilled across a mixed fleet operation, consisting of electric and mechanical trucks.

Following Immersive Technologies development of a new standardized process, a 60% saving in trainer hours and 70% saving in training durations were achieved.

REF#TR0815

Stevin Rock, United Arab Emirates

Stevin Rock faced a huge shortage in the availability of a skilled workforce, with the regional workforce not having previously been exposed to structured professional training.

The customer invested in multiple simulators and Conversion Kits® to support their training efforts. Syllabus, curricula and lesson plans were developed which produced a range of positive results, including reductions in all accident types involving mobile plant, greater safety awareness, and reduced downtime.

REF#TR0311

Newcrest Mining Limited, Papua New Guinea

The Lihir operation faced many challenges in training new operators; multiple regional dialects, many not having previously driven a motorized vehicle, an average of 8th grade education level and no concept of time.

Lihir trains an average of 115 operators to a competent standard per year using simulation as one of the foundational learning tools.

Sign up and receive our latest news and offers. Subscribe today

Sign up and receive our latest news and offers.