Increase Mine Productivity using Data Analytics and Targeted Operator Training

It’s one of the biggest challenges facing mine sites today, “how can we increase productivity without compromising safety or increasing cost?” Immersive Technologies, a leader in mining training solutions, says compelling results prove putting more focus on operator behavior and skills will deliver higher output. They recently released a number of case studies proving how their simulation training and professional services delivered cycle time, spot time, swing time and bucket fill factor improvements.

Recently released case studies from Immersive Technologies provide details as to how their simulation training and professional services delivered cycle time, spot time, swing time and bucket fill factor improvements.

“We know that equipment performance is heavily dependent on operator skill, knowledge and attitude. Our unique approach ensures our customers focus on the right issues that will deliver the highest returns. We work closely with mining customers and OEM’s to ensure the technology is properly integrated and quantified results are achieved,” says Bryant Mullaney, Global Professional Services Manager, Immersive Technologies.

Adding to their already extensive catalogue of quantified business improvements, the recently released case studies show examples of productivity increases achieved in mining operations through the use of data analysis and training solutions from Immersive Technologies. The newly added case studies span three countries and three commodities.

One case study (PR0511) explains details of a customer who was under pressure to show marked improvement in their overall production across all of their mine sites with an identified risk regarding the absence of a formal Dragline operator training strategy.

The Customer partnered with Immersive Technologies to develop and implement a structured training curriculum through Training Systems Integration (TSI) and to drive ROI through targeted training, using simulators.

In-pit data was collected through an onboard data capture system and analyzed in order to define the optimal training interventions. Targeted one-on-one skill training sessions were conducted to close gaps for each dragline operator.

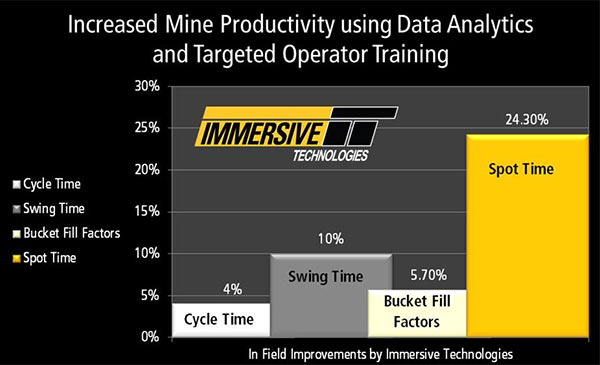

A comparison of operator performance in the six months before and six months after the training showed:

- 4% improvement in cycle times

- 10% improvement in swing times

- 5.7% improvement in bucket fill factors

At one site (case study UM0913) an initial training needs analysis demonstrated an opportunity to improve haul truck spot times. Data analysis revealed that only 20% of the workforce were responsible for the majority of lower than expected productivity.

Immersive facilitated a cross functional team consisting of stakeholders from Production,Maintenance, Training and Continuous Improvement. Upon the completion of the training initiative average spot times were reduced by 9 seconds.

The final case study (PR00613) recently released by Immersive Technologies spanned three mine sites where truck operators underwent simulator based training to improve truck cycle times.

Simulator data was used to track progress of production specific skill and knowledge retention. Infield data was collected and analyzed both before and after training. The end result was an average of 24.3% improvement in spot times across all three sites.

“Following work with 230+ sites globally we believe that significant quantifiable improvement can be achieved at any mining operation. We understand that every mining operation and training center has different needs and priorities that require customization, flexibility and consultation to maximize outcomes. We provide customized solutions which can include trainers, consultants, supervision and technology including flexible hire of Simulators,” Mullaney says.

For more information on these case studies or achieving results at your site email or contact any of our 14 offices: https://www.immersivetechnologies.com/contact/

###

About Immersive Technologies

Immersive Technologies is the world’s largest, proven and tested supplier of surface and underground Advanced Equipment Simulators to the global mining industry. The company has achieved this unique position by focusing on its mission to increase Customer profitability by optimizing the safety and productivity of their operators. Immersive Technologies’ Advanced Equipment Simulators are helping hundreds of mining companies around the world to increase their equipment operators’ safety and site profitability through effective simulation training.

Immersive Technologies provides its customers with the most effective Advanced Equipment Simulators available. This is made possible through the formal licensing and technical information alliances Immersive has established with the leading Original Equipment Manufacturers (OEM), including: Caterpillar Global Mining, Hitachi, Komatsu and Liebherr. These unique alliances provide Immersive Technologies with access to the OEM’s proprietary and confidential machine technical information that is required to correctly simulate the OEM’s machines and is not available through other public or dealer channels.

With advanced simulator modules deployed in 55 countries, Immersive Technologies is dedicated to provide outstanding service. To deliver on this commitment the company has customer sales and support offices located close to its customers in Perth and Brisbane Australia, Salt Lake City and Tucson USA, Fort McMurray and Vancouver Canada, Zacatecas Mexico, Lima Peru, Santiago Chile, Belo Horizonte Brazil, Johannesburg South Africa, London United Kingdom, Jakarta Indonesia, Kolkata India and Moscow Russia..

Immersive has the global mining experience, innovative technology, product range, OEM relationships, proven support commitment and industry vision to partner with you to ensure your simulator training solution delivers the significant results you expect.

Sign up and receive our latest news and offers. Subscribe today

Sign up and receive our latest news and offers.

Login

Login