*eLearning, Classroom, Virtual Classroom and In-field Training components are usually provided by Komatsu for FrontRunner® Autonomous Haulage System (AHS).

Workforce Development Model for Autonomous Haulage mining

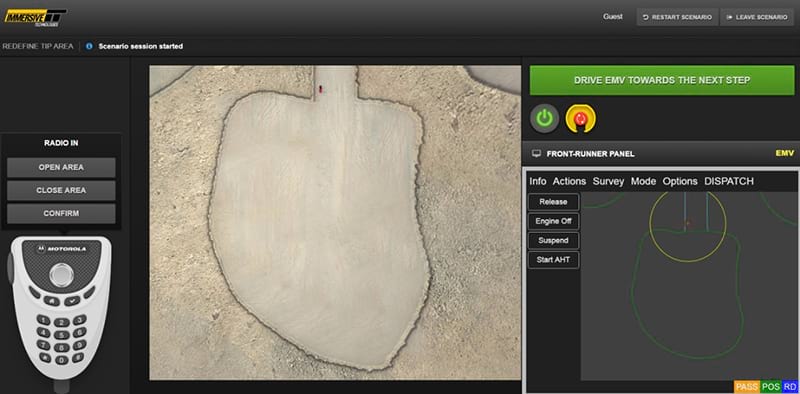

Innovative technologies have enabled a more immersive training experience, enabling majority of initial training for autonomous haulage operations to be completed virtually using tools such as Machine Inspection, Virtual Classroom and Equipment Simulators.